The super strong, super thin and super versatile new material could change the way multiple products are made.

It would be hard to find a material that’s gotten the mobile industry more excited than graphene, a super-thin, wonder material made up of carbon atoms that are layered together in hexagonal shapes. Demonstrations of ways graphene could be used to develop new types of optical communications, transparent circuits that can be bent and twisted, neural implants, stickers that can track health, and printed sensors for all sorts of Internet of Things applications will be on display at the Mobile World Congress in Barcelona, Spain Feb. 26-March 1.

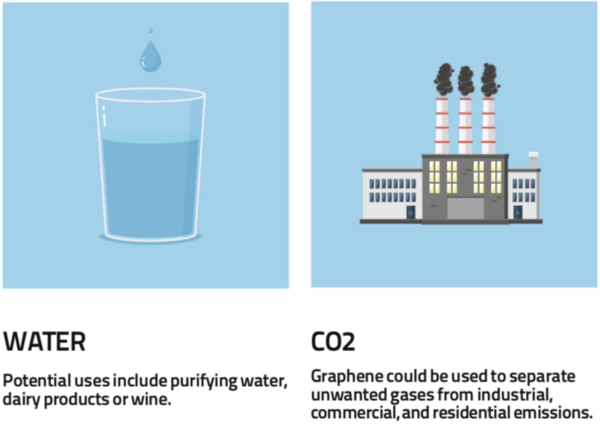

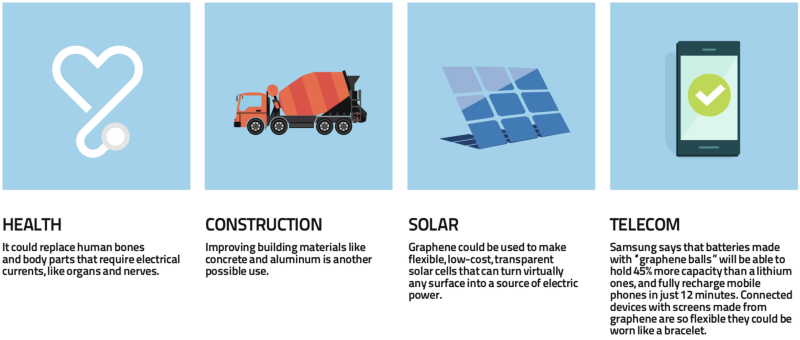

The mobile industry is interested because graphene could usher in entirely new types of connected objects. Apple, for instance, has been awarded several patents for designs that incorporate graphene, including graphene solar panels printed inside the touch screen to allow constant recharging; an entire smartphone that can be folded in half; a heat dissipater that would prevent smartphones from overheating; and a graphene-based battery system for smartwatches that conducts heat from the wrist to keep the gadget charged. Samsung alone has applied for at least 405 graphene-related patents around the world, according to press reports, and last November announced it had developed a “graphene ball” which, when combined with lithium batteries, allows for five times faster charging of Samsung phones. One could theoretically fully charge a smartphone in 12 minutes, the company says. There are good reasons why graphene should also be on the radar of executives in other industries. Developed by two researchers at the University of Manchester in the U.K., Andre Geim and Konstantin Novoselov — whose work won them the Nobel Prize in Physics in 2010 — graphene is incredibly stable and very thin, yet also a strong conductor of electricity, heat and light. According to an article on Singularity Hub, a website operated by Singularity University, potential uses include purifying water, dairy products or wine; production of pharmaceuticals; separating unwanted gases from industrial, commercial and residential emissions; replacing human bones and body parts that require electrical current, like organs and nerves; improving building materials like concrete and aluminum by making them stronger and lighter; making pipes and storage tanks corrosion-resistant; developing stronger adhesives; creating flexible, low-cost, transparent solar cells that can turn virtually any surface into a source of electric power and building bigger and lighter wind turbines.

Revolutionary Potential

Such revolutionary potential has triggered an international arms race of sorts, with governments pumping huge sums of money into development. In the U.S., the federal government has awarded almost $264 million in graphene-related research grants over the past decade to recipients ranging from the Massachusetts Institute of Technology to corporations like IBM. Last fall, the National Graphene Association, which is based in Oxford, Mississippi, announced it was co-sponsoring the Center for Graphene Research and Innovation at the University of Mississippi. It also created a new industry advocacy group called the American Graphene Institute, along with a graphene venture fund to invest in related products.

In the U.K., the government has earmarked $166 million for graphene programs. That includes at least $80 million for the National Graphene Institute and a new Graphene Engineering Innovation Center based at the University of Manchester, where it all started.

Trumping them all, however, is the European Commission, which in 2014 announced it would spend $1.22 billion over 10 years on the Graphene Flagship, a partnership of 125 research organizations, governments, and industry that aims to take the new material out of labs and into commercial products. The Graphene Flagship is organizing the pavilion at MWC for the third time this year. Frank Koppens, professor at the Institute of Photonic Sciences in Barcelona and scientific chair of the Graphene Pavilion, says he believes graphene is a disruptive technology that could have a huge impact on society.

Not Yet Ready for Prime Time

The trouble is, it is not quite ready for prime time. Graphene is made in limited batches, in carefully controlled lab settings, has been effective in creating high-quality material than can be used in experiments. But it has proved harder to produce high volumes that maintain the same structural integrity and offer the fullest benefit of things like conductivity, says Koppens.

The challenges in realizing graphene’s potential might best be understood by gazing inside an Italian shoe. The sole of a recently developed open- toed sandal called “Freshoes” was the result of a partnership between the Tuscany-based shoemaker Fadel and BeDimensional, a startup that was spun out of the Italian Institute of Technology. The bottom of the shoe contains a mixture of polyurethane and light-weight, super-strong graphene which leverages the latter’s ability to conduct heat and energy to make a sole that keeps feet unusually cool. While the shoe is a neat, niche consumer product, for Vittorio Pellegrini, a BeDimensional co- founder, it also represents graphene’s two main limitations: The industry still can’t produce it in mass quantities, which would make it cheap enough for wider use beyond such novelty products. And a tremendous amount of work must still be done to understand how graphene can be combined with other materials to make something as basic as an analog shoe, never mind a futuristic bendable wearable packed full of atomic-size circuitry that could create a whole new class of consumer electronics.

“We know that graphene is an exceptional material, but we have not identified the killer applications yet,” says Pellegrini. “And a big reason for that is that production is just not scalable.”

Large corporations are reluctant to invest too much in product development until they are sure the material can be made in sufficient quantities at reasonable prices, says Koppens, the scientific chair of the Graphene Pavilion. So for the moment, he and his teams are focused on developing use cases and products that demonstrate the power of graphene in order to continue building interest from the industry. Imagine a camera for your smartphone with the power of night vision goggles and the ability to identify the various substances in milk to tell you if it’s contaminated. Or light-based data transfer systems for new data centers that don’t generate heat and therefore don’t need massive expensive cooling systems. Or a sticker that you slap on your arm that contains a sensor to measure UV light and sends an alert to a smartphone if you’re getting too much sun. “For any new material that makes it into applications, it takes a long time,” Koppens said. “And people forget that. But I think there has been a lot of progress and I feel optimistic. There’s still a challenge, but it’s a more realistic challenge now.”