Global demand for computing power is surging and leading data center players are readying a massive deployment of capital—$1.8 trillion from 2024 to 2030—to meet the need, according to Boston Consulting Group. Construction spending on U.S. data centers alone reached an all-time high of $40 billion in June, as technology giants continue pouring billions into AI infrastructure. The build-out has other important costs. The massive amounts of energy and water needed to run these data centers has a significant environmental impact as does the cement that goes into their construction.

Concrete is the most widely used construction material on Earth. Production of its key binding ingredient, Portland cement, contributes approximately 8% of global CO2 emissions. It also drives unsustainable demand for sand, stripping riverbeds and coastlines and damaging ecosystems.

New approaches to making cement are expected to play an important role in abating that impact. Sublime Systems , one of over 40 “green cement” scale-ups, uses electricity and non-carbonate materials to produce low-emissions cement, reducing CO2 emissions by 90% compared to ordinary Portland cement, without compromising strength.

The U.S. green cement scale-up has inked a deal with Microsoft to supply 623,000 tons of low-carbon cement over six years for the build out of its data centers and it is in advanced discussions with other hyperscalers to do similar deals, Joe Hicken, Sublime Systems’ Senior Vice-President, Business Development and Policy, said in an interview with The Innovator. With financial backing from the world’s building materials and construction companies, including Holcim, CRH, Siam Cement Group, and Suffolk Construction, the company, a spin-out of the Massachusetts Institute of Technology co-founded by Leah Ellis and Yet-Ming Chiang , has been deploying cement in real-world projects since 2023. It is developing its first commercial facility in Holyoke, Massachusetts, which is scheduled to open in 2028 and produce 30,000 tons per year.

Green cement is just one example of how technologies can help combat environmental challenges, according to an October report published by the World Economic Forum in collaboration with Frontiers, an open science publisher.

“The urgent realities of climate change are clear, but what is less visible are the technologies already available and how they can be used in new ways to deliver solutions,” Jeremy Jurgens, Managing Director, World Economic Forum said in a statement. “This research provides global leaders with the foresight they need to act at the necessary speed and scale.”

Like green concrete, green ammonia production and methane capture and utilization focus on advances in material and chemical processes to reduce emissions and decarbonize key sectors. Other technologies – like next-generation (next-gen) bi-directional charging and modular geothermal – offer innovative ways to consider energy systems for greater efficiency, flexibility and resilience. Advances in biotechnology have also led to precision fermentation for alternative proteins and microbiome engineering for soil health, which can enhance food security, reduce agricultural emissions and restore ecosystem function. When different advances in technology converge, they enable breakthroughs like automated food waste upcycling, timely and specific Earth observation and regenerative desalination. These technologies are highlighted in the Ten Emerging Technology Solutions for Planetary Health report, which includes a forward from Johan Rockstrom, Director, Potsdam Institute for Climate Impact Research.

In the report Rockstrom points out that the critical Earth processes that regulate the stability and resilience of the planet are being pushed beyond safe limits. With mounting evidence that we have already exceeded Earth’s “safe operating space” and breached seven of the nine planetary boundaries, there is an urgent need for solutions that mitigate greenhouse gas emissions, maintain biosphere integrity, enable resource efficiency and repair Earth systems, he says.

Novel cement-free green concrete technologies do just that, cutting demand for extracted raw materials and easing pressure on planetary boundaries related to climate change, land-system change, biogeochemical flows and novel entities, the report says. They eliminate Portland cement altogether and instead use binders derived from industrial byproducts or construction and demolition waste (CDW).

From The Romans, To The Industrial Revolution, To Now

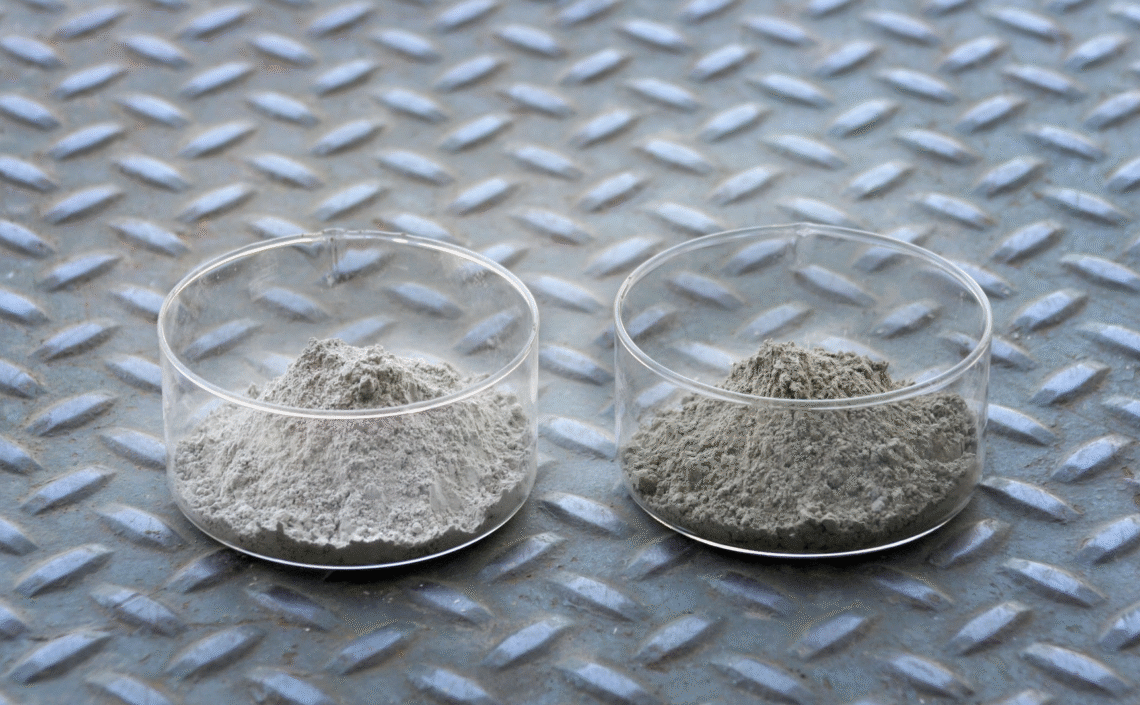

Sublime’s process foregoes the kiln, the most energy-intensive part of Ordinary Portland Cement (OPC) production and replaces it with a targeted electrochemical process—reducing the energy intensity of production by 30%-40%. The approach also avoids emissions from CO2, CO, NOx, SOx, mercury, and particulates. It converts low-value rocks and toxic industrial solid waste into clean cement and pure minerals. The company says it upcycles the whole rock, leaving nothing wasted, compared to ~50% of limestone feedstock that is lost as pollution in OPC manufacturing. And it says that its approach, which is based on an old Roman recipe for cement used in the Coliseum, is more durable than today’s OPC cement in almost every use case. “Our technology avoids waste and pollution to make clean, beautiful, durable cement anywhere, out of almost anything,” says Sublime Systems. What’s more its, ambient-temperature process makes cement that is whiter in color, a quality desirable for aesthetics and heat reflectivity. (see the photo).

Some other green cement technologies also enable CO2 mineralization during curing, where CO2 is actively introduced and sequestered into the concrete matrix, according to the Forum’s report. This process not only eliminates emissions from traditional cement production but also creates a permanent storage route for captured CO2 .Geopolymer binders, a key example of cement-free systems, are produced by chemically activating aluminosilicate-rich materials such as fly ash, blast furnace slag or milled CDW. Use of these waste materials displaces the use of virgin limestone, sand and gravel, thereby avoiding the energy-intensive, high-temperature, high-emission reactions required to make Portland cement. Geopolymers divert waste from landfills and circumvent resource extraction, which supports circular, lower-impact construction practices.

When coupled with CO2 curing techniques, the result is a durable, lower-carbon concrete that stores captured CO 2 while meeting performance needs, says the Forum report. Experimental methods have mineralized up to 45% of the injected CO2 – permanently storing it without compromising structural performance. In one demonstration, researchers constructed a full-scale, one-story home using prefabricated components made entirely from CDW and CO2 enhanced materials.

The Role Of Policy And The Private and Public Sectors

Despite the demonstrated benefits and the urgency to address environmental issues no green concrete company has scaled to date, notes Hicken.

Like any other clean tech innovation green cement needs to overcome conceptions of what green means. “We shy away from the term ‘green cement’ from a communications standpoint because the immediate, first reaction of people is ‘what sacrifices do I need to make to adopt something like this?’,” says Hicken. “Our intrinsic value is that we can manufacture cement more efficiently and cleanly. It is also very complicated to introduce new materials, so we need to be clear that it doesn’t require anything dramatically different than is done today. And, the built environment can’t afford any physical risk, so we also need to get across that we are delivering products that are designed to be stronger and more durable than the materials concrete is made from today.”

Cost is always an issue for any new clean technology. “To get to price parity we need economies of scale,” says Hicken. “Today we operate a pilot facility at ton scale that delivers real materials in the real world, but we need to be able to produce hundreds of thousands of tons.”

Sublime Systems is counting on the help of both the private and the public sector to achieve that goal.

The Forum’s First Movers Coalition helps create markets by getting big companies to invest in emerging technologies that aim to decarbonize hard to abate sectors. The deal between First Movers Coalition member Microsoft, a company that typically doesn’t directly buy cement, and Sublime, is an example of how such agreements help companies scale.“The hyperscalers like Microsoft who are driving innovation in compute and AI are also being strategic about managing their supply chains at scale and Sublime fits into their long-term plan of always building with the most efficient, cleanest tools available to them,” says Hicken. “Cement is one of them. “

The U.S. scale-up is counting on other companies to do the same. “Our success depends on the titans of industry,” he says.

The public sector’s support is also vital, as cement plants are capital intensive. The U.S., one of the top importers of cement worldwide, wants to increase domestic manufacturing. Sublime could help by strengthening domestic supply chains., creating jobs and reducing emissions. However, U.S. President Donald Trump’s administration recently canceled an $87 million grant issued to Sublime Systems for its low-carbon cement manufacturing plant in Holyoke, as part of the government’s elimination of nearly $8 billion in funding for more than 200 U.S. projects aimed at reducing carbon emissions.

Sublime Systems says it is now looking to Europe, which is focusing on industrial decarbonization. “European policy makers want to invest” in clean technologies, says Hicken.

The U.S. scale-up’s cement meets performance-based standards used in the U.S. (the ASTM International standard performance specification for hydraulic cement) but standards are not uniform globally. In Europe, for example, along with performance requirements cement standards also specify the chemical crystalline composition of the powder used to make cement. Global standards need to be adopted and be flexible enough to allow for innovation in the chemical composition so that new approaches can come to market quickly and scale globally, Hicken says.

Like green cement, the nine other solutions in the report need investment, infrastructure and an enabling policy environment to scale. “Open science and cross-sector partnerships are essential if we’re to turn innovation into impact,” Frederick Fenter, Chief Executive Editor, Frontiers, said in a statement. “This report shows that while no single technology is a silver bullet, together they can help us bend the curve towards a healthier planet and a more sustainable future for all.”

This article is content that would normally only be available to subscribers. Become a subscriber to see what you have been missing.